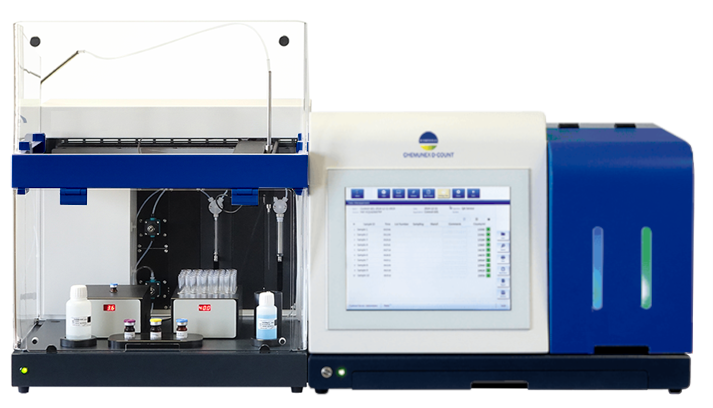

MicroVal approved the issuing of a new certificate for iQ-Check EB for the detection of Enterobacteriaceae, manufactured by Bio-Rad Laboratories. As indicated by its name, this method is designed for the detection of Enterobacteriaceae in infant formula, infant cereals (with or without probiotics), and related ingredients with test portion up to 375 grams.

The study was performed by ADRIA, and conducted in accordance with ISO 16140-2:2016 and ISO 16140-2/A1:2024. The validation covered the following components:

- iQ-Check Enterobacteriaceae kit

- FDRS

- CFX96 Deep Well and CFX Opus Deep Well PCR instruments

The method involves enrichment of samples in prewarmed Buffered Peptone Water (BPW) with a PIF supplement, followed by FDRS treatment, lysis, and PCR analysis. Positive PCR results are confirmed using either the reference method (ISO 21528-1:2017) or the alternative method based RAPID Enterobacteriaceae agar, where the presence of typical colonies confirms the result.

This validation confirms the reliability, robustness, and applicability of the iQ-Check EB method for detecting Enterobacteriaceae in sensitive food matrices intended for infants.

An extension of the validation was approved in June 2025 for use with the updated CFX Maestro IDE software (version 4.0).

The certificate and the detailed summary report, number 2018LR80, are available on our website.